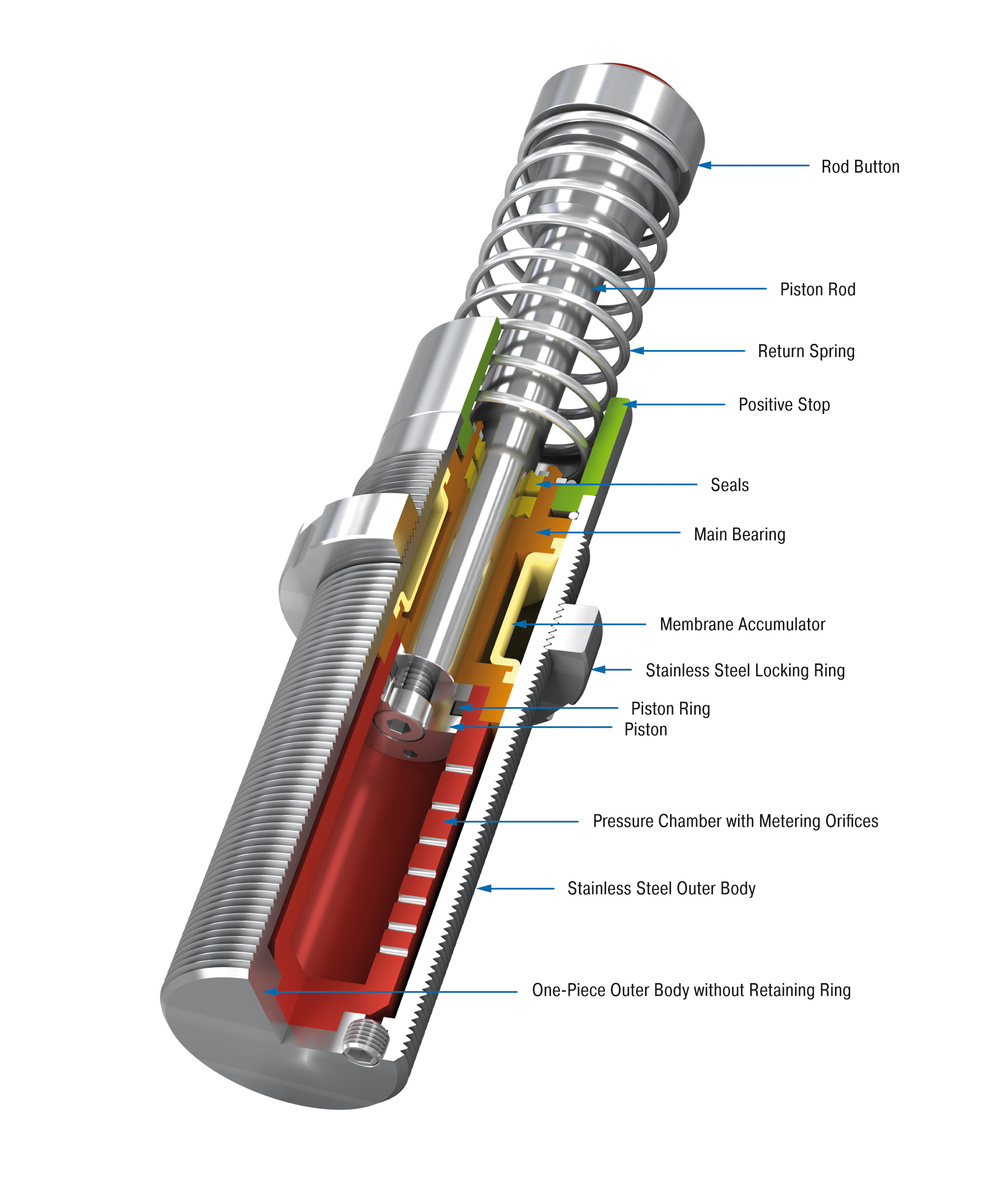

Industrial Shock Absorbers

MC33-V4A to MC64-V4A

Optimum corrosion protection

Self-Compensating, Stainless Steel

Energy capacity 170 Nm/Cycle to 5,650 Nm/Cycle

Stroke 23.1 mm to 150 mm

Just like the standard product family, the MAGNUM stainless steel models are distinguished by their robust, modern sealing technology, high energy absorption in a compact design, integrated positive stop and a wide damping range. Equipped with a PU head, they are available in thread sizes M33x1.5 to M64x2 with damping strokes up to 150 mm.

These self-compensating industrial shock absorbers made of stainless steel from ACE are mainly used in the food, medical, electro and offshore industries, but also in many other markets.