Industrial Shock Absorbers

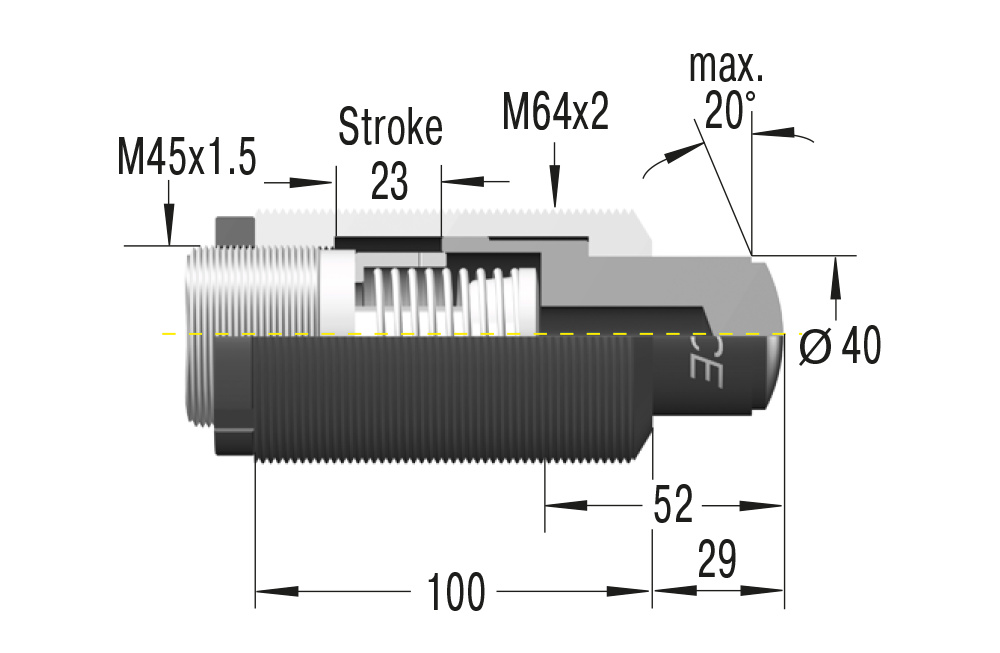

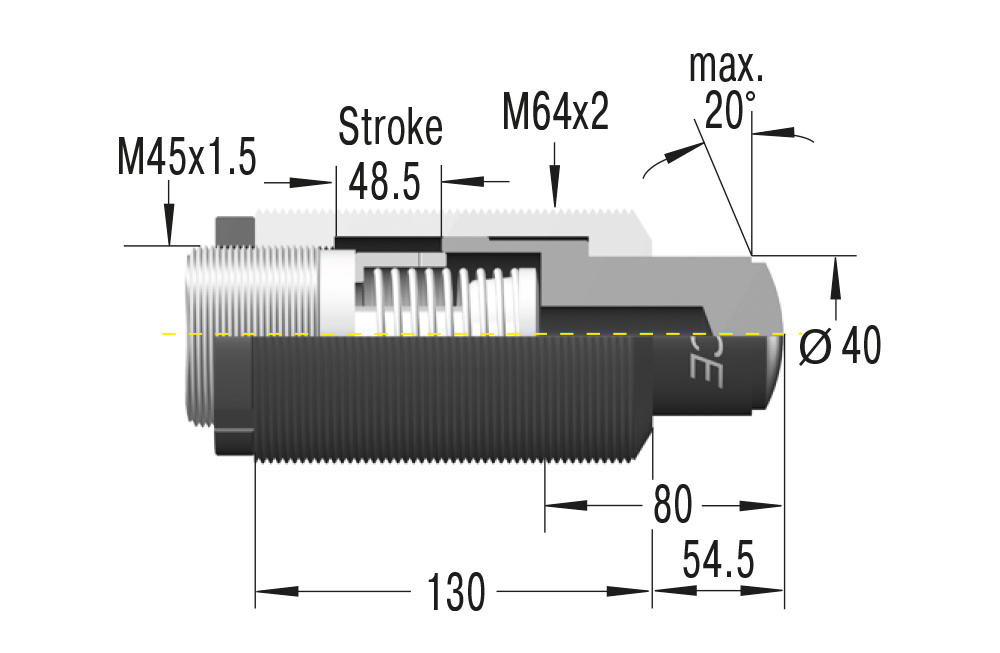

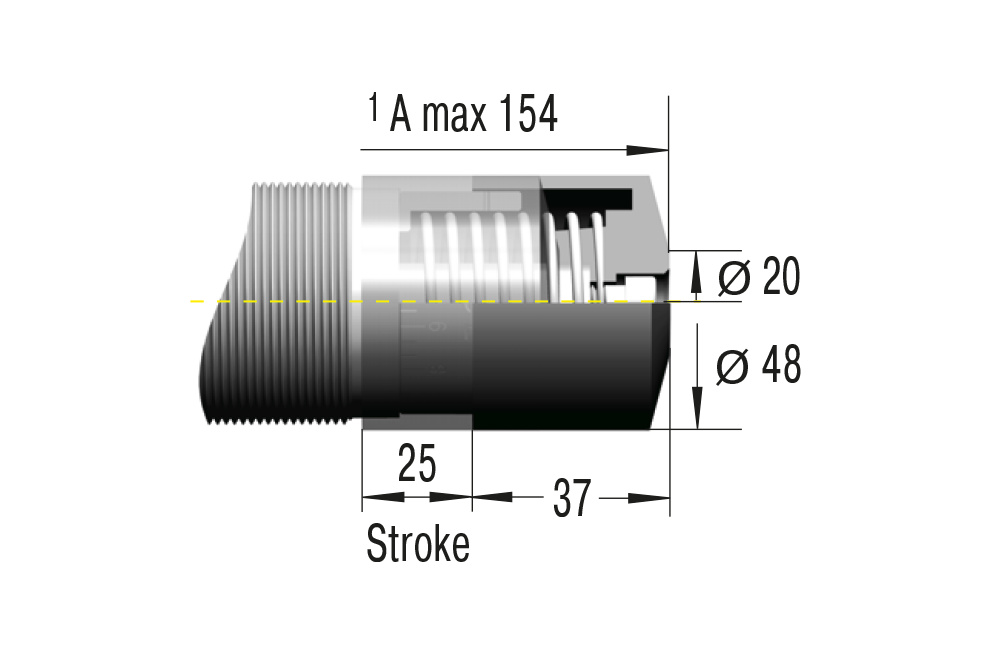

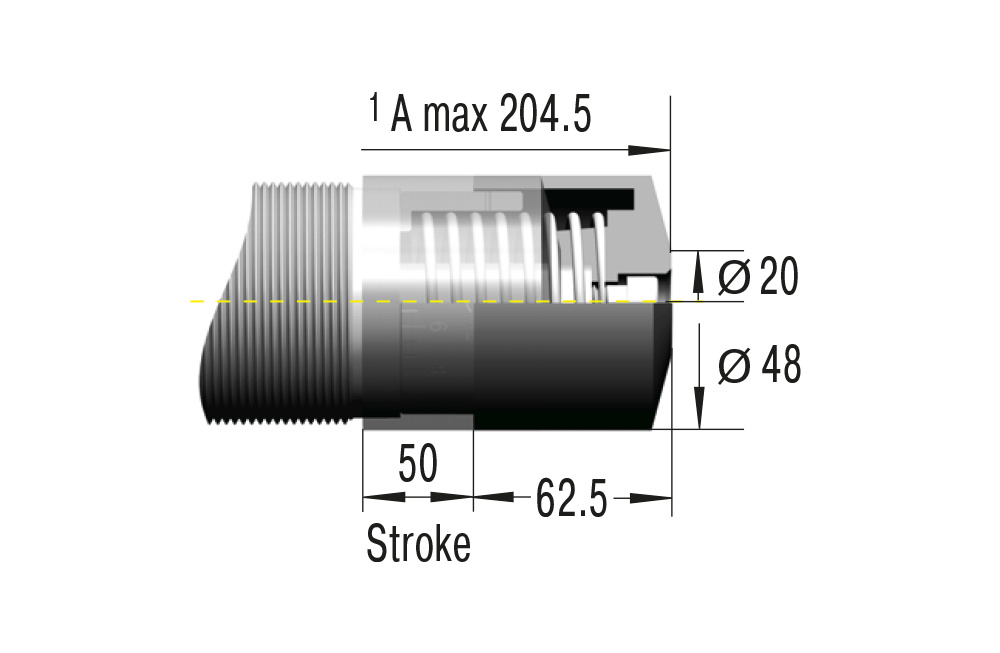

MC4575EUM-4-LT

Extreme low temperatures

Self-Compensating, use at -50 °C to +66 °C

Energy capacity 1,130 Nm/cycle

Stroke 73.9 mm

There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

_FA_IMG_Single-01-cut-Labels_RGB-L_EN.jpg)

_FA_IMG_Single-01-cut_RGB-L.jpg)

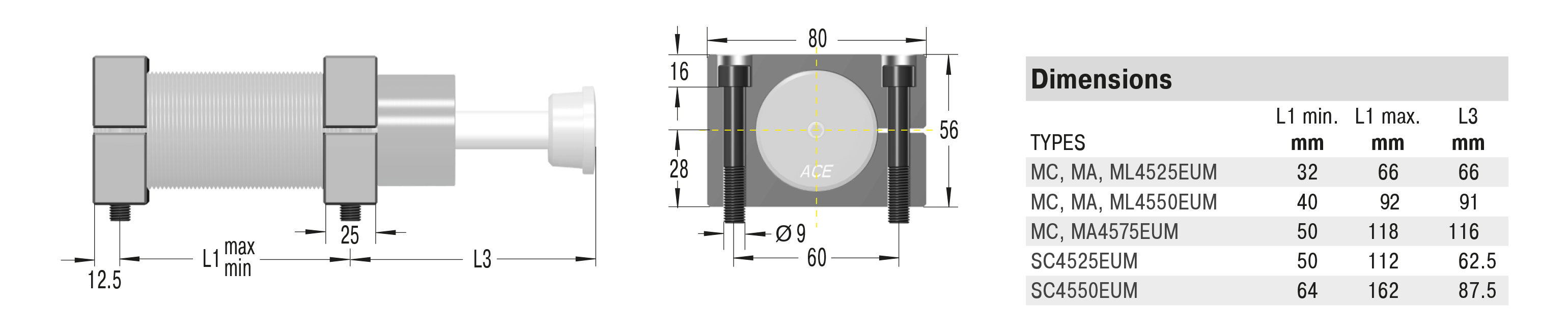

_GT_TECHdraw-F_RGB-L_EN(-US).jpg)