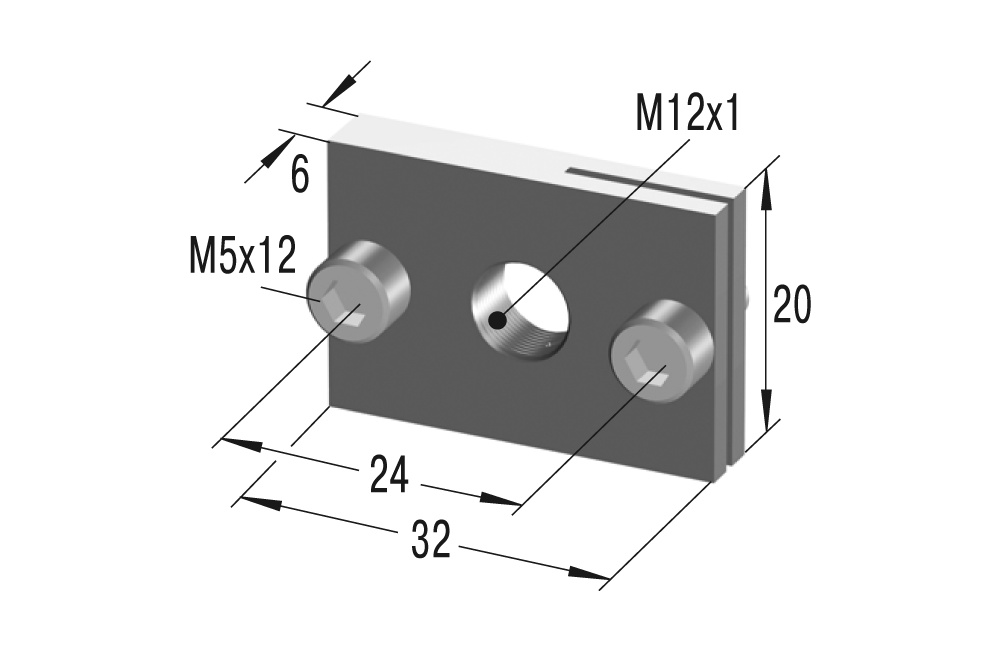

Hydraulic Feed Controls

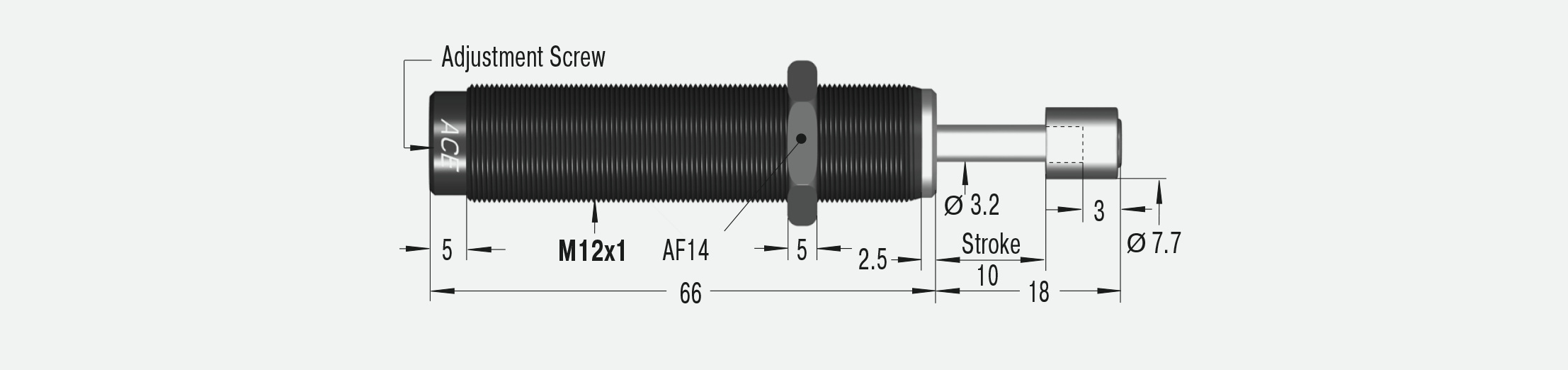

MA35EUM

Designed for applications with low precision requirements

Adjustable

Energy capacity 4.0 Nm/cycle

Stroke 10.2 mm

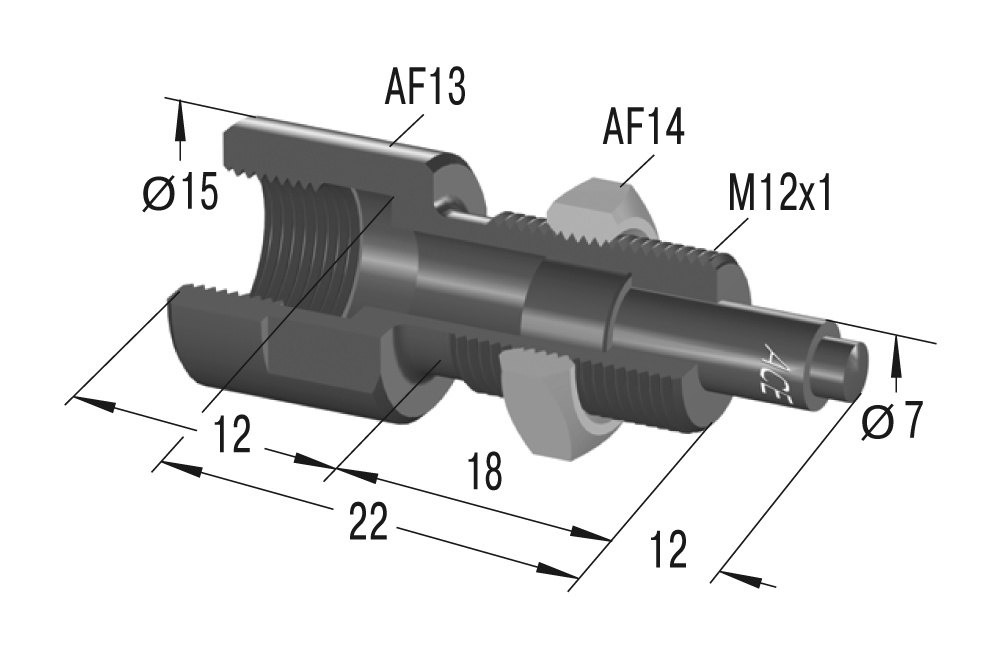

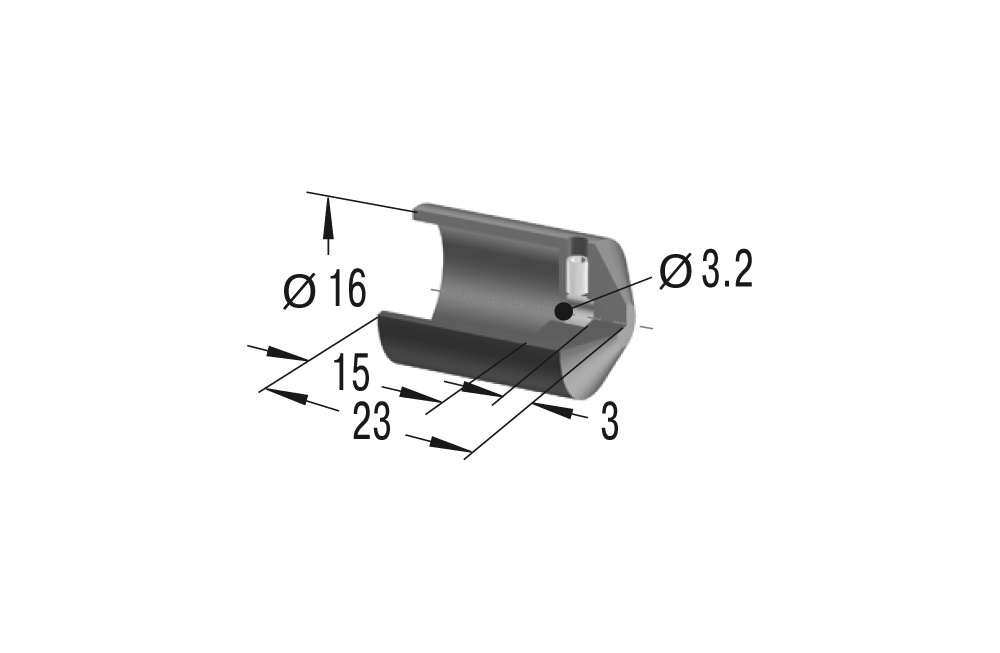

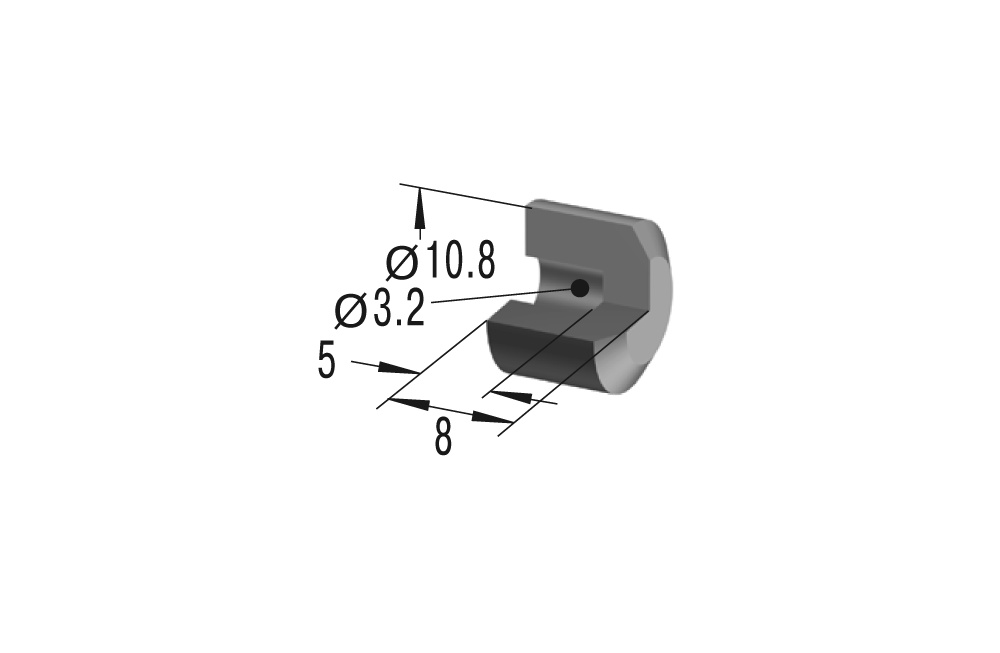

There are also plenty of accessories for the FA, MA and MVC models. All products are ready-to-install, maintenance-free, stable in temperature and avoids stick-slip effect. Speeds from 12 mm/min. can be driven at a low thrust force using the adjustment screw on the base of the hydraulic control.

Hydraulic feed controls with the designations FA, MA and MVC are especially used in handling modules or linear carriages and also for applications with changing usage data.

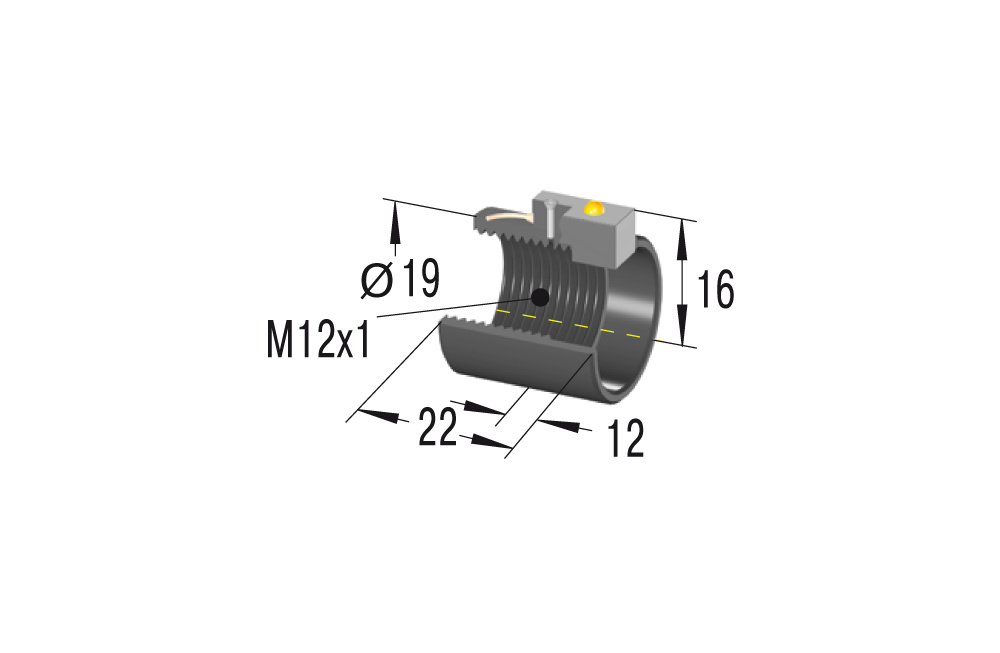

_FA_IMG_Single-01-cut-Labels_RGB-L_EN.jpg)

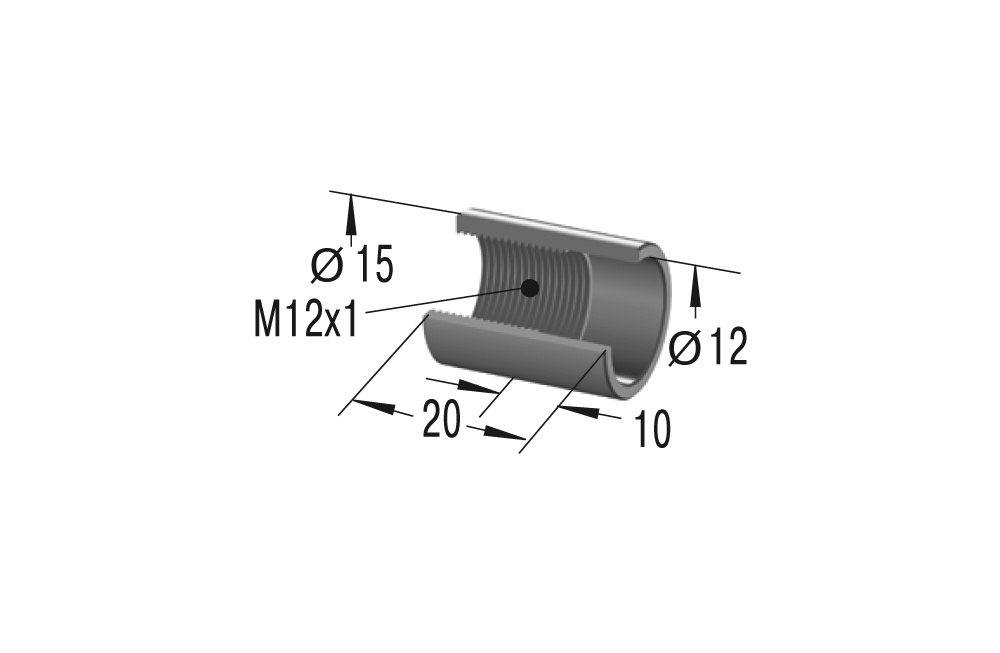

_FA_IMG_Single-01-cut_RGB-L.jpg)