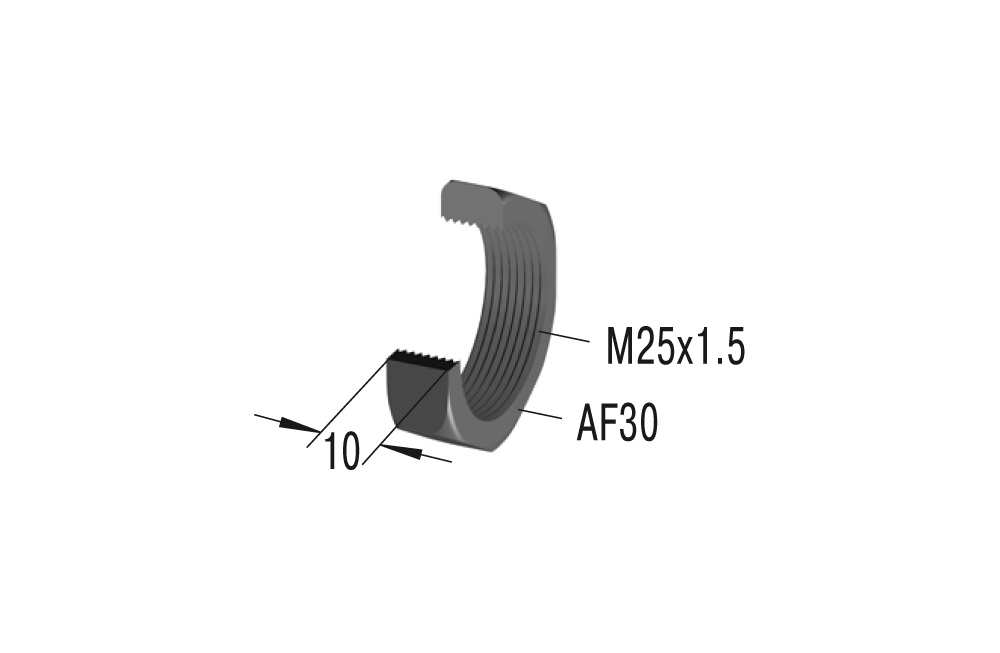

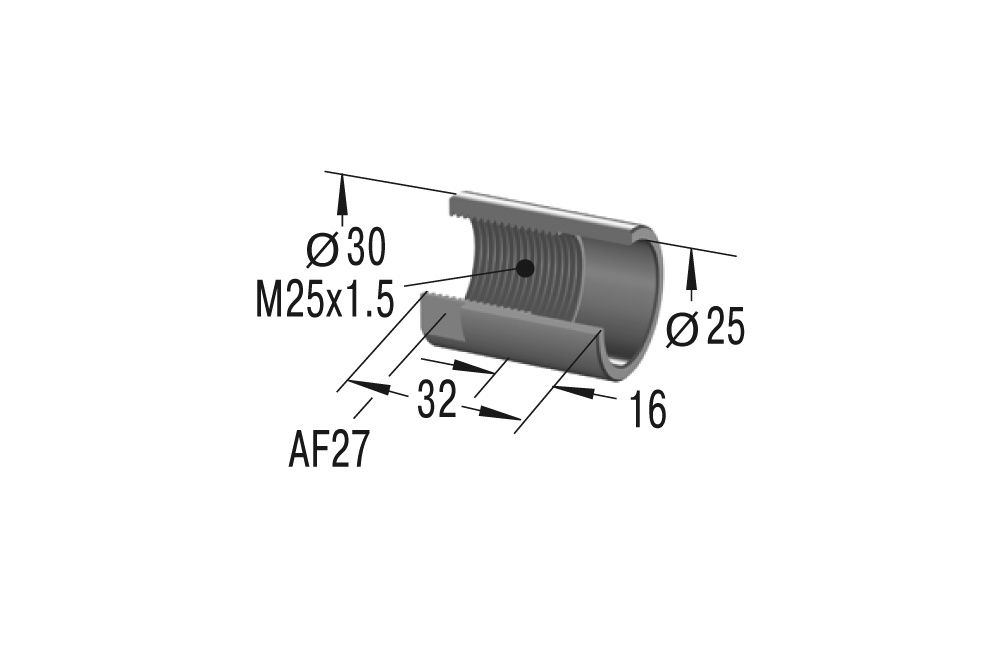

Miniature Shock Absorbers

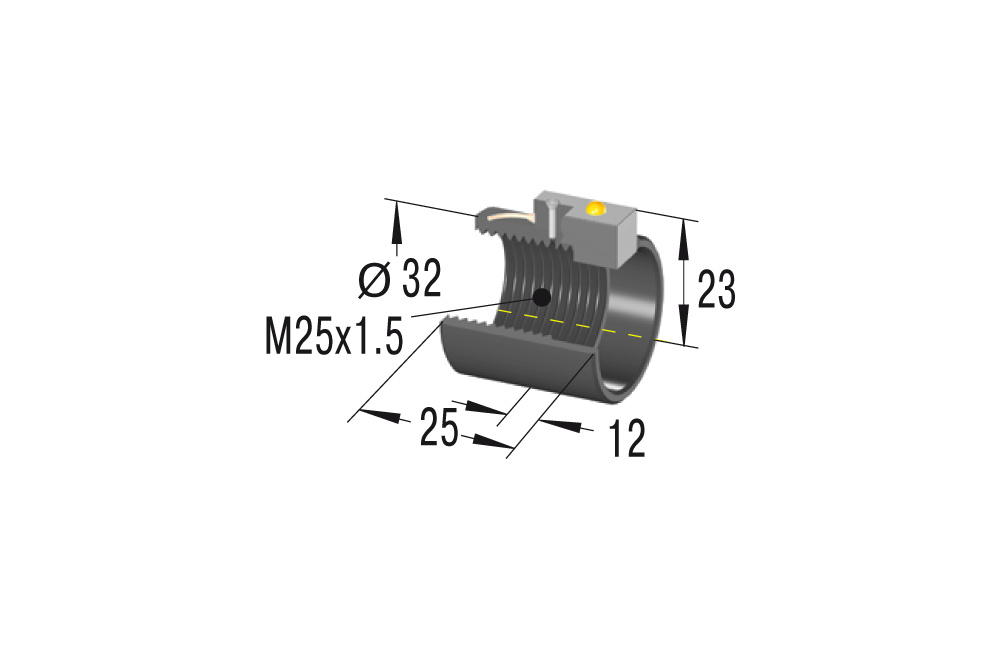

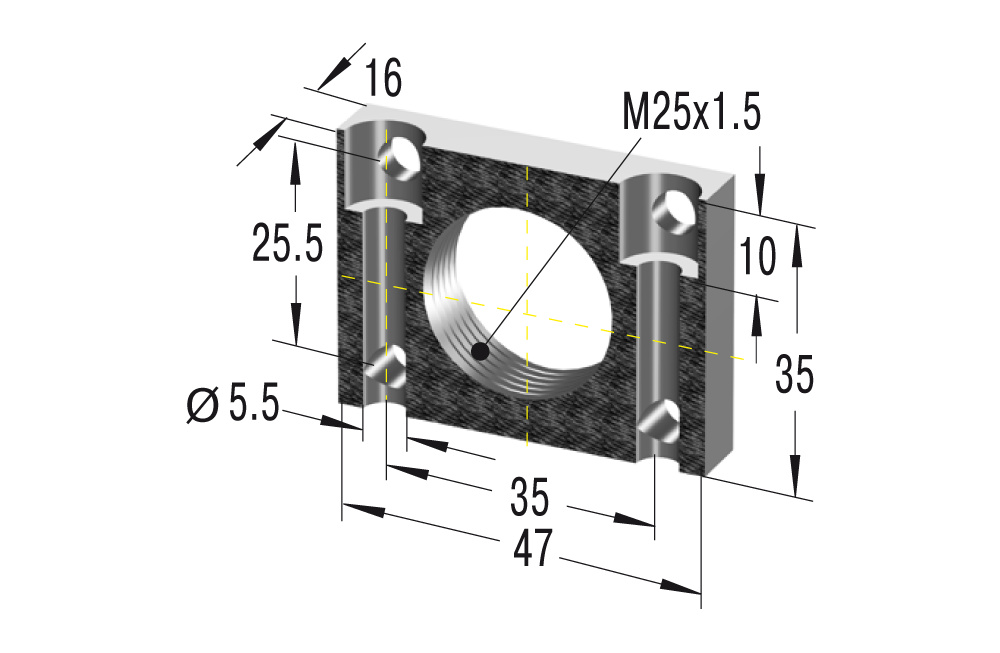

SC925EUM-1-880

Long stroke and soft impact

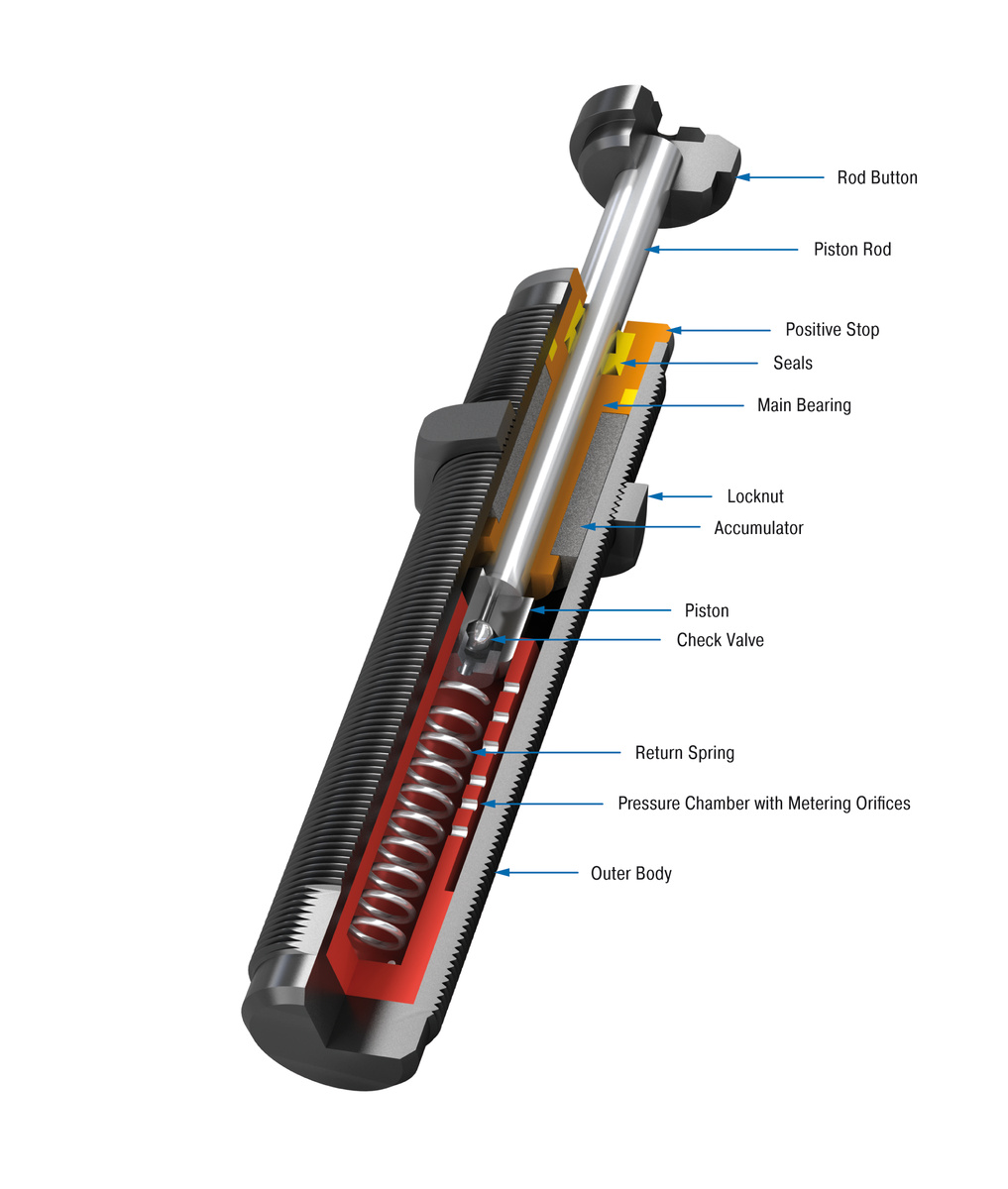

Self-Compensating, Soft-Contact, without Rod Button

Energy capacity 110 Nm/cycle

Stroke 40 mm

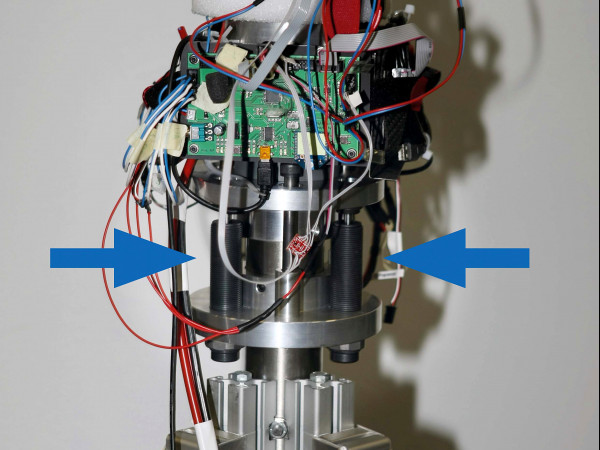

These maintenance-free, ready-to-install hydraulic machine elements are equipped with an integrated positive stop. The use of side load adapter allows impact angles of up to 25°. Thanks to the designed overlapping effective weight ranges, these dampers cover an effective load range of below 1 kg to more than 2,000 kg!

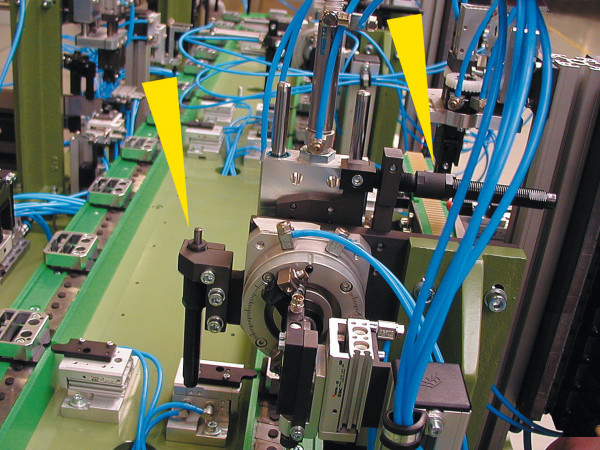

The miniature shock absorbers from the SC190 to SC925 product family are used in mechanical engineering and primarily in the areas of handling and automation.

-880_M_TP_TECHdraw-F_RGB_EN.jpg)